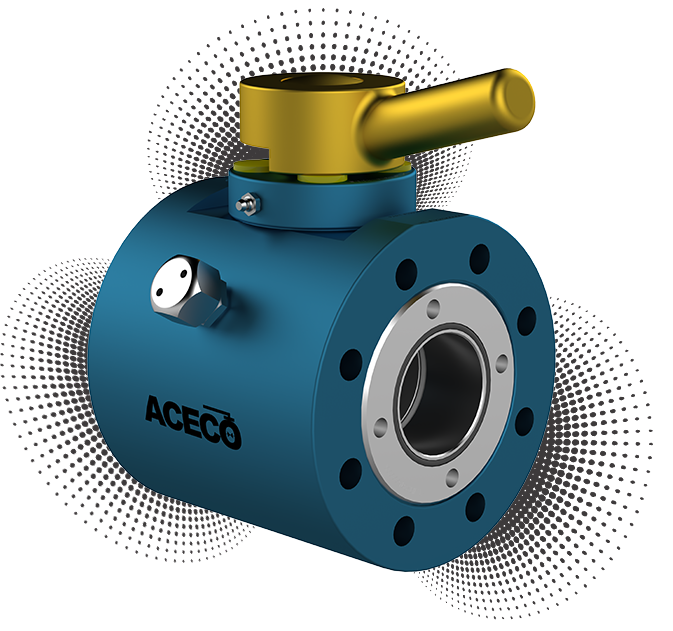

Double Ball Valve

Subsea Valve

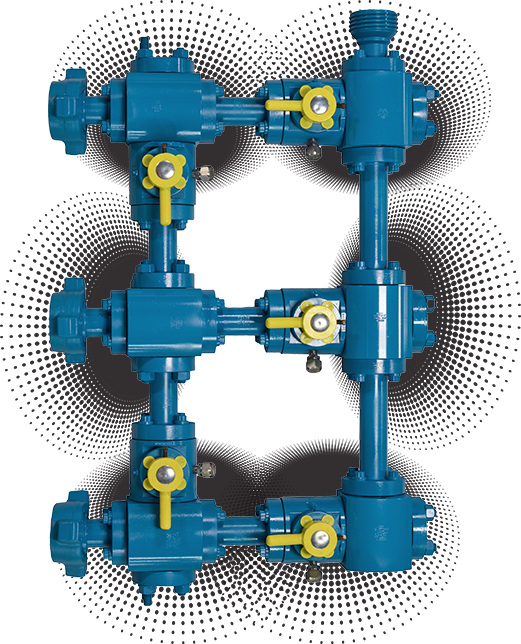

Manifold System

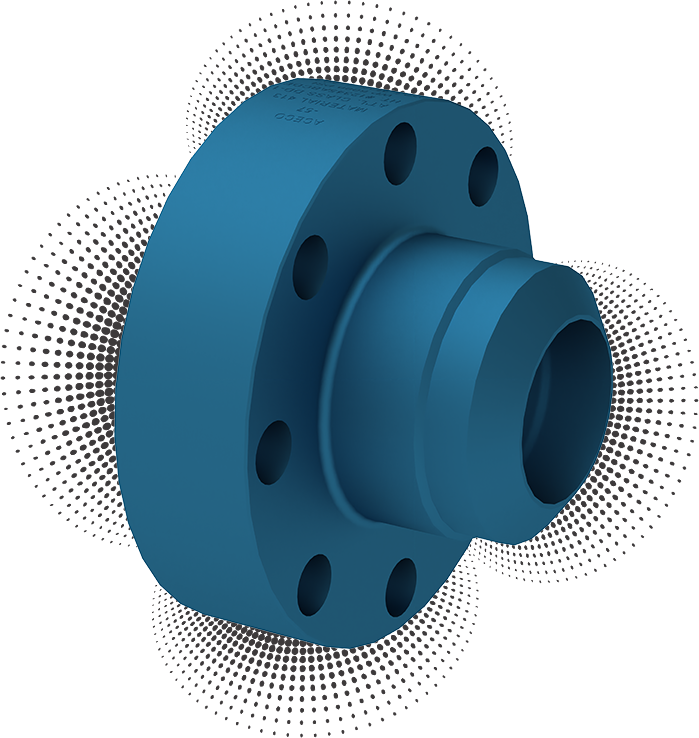

Gas Measurement Flanges

Floating Ball Valve

Check Valve

Pigging Valve

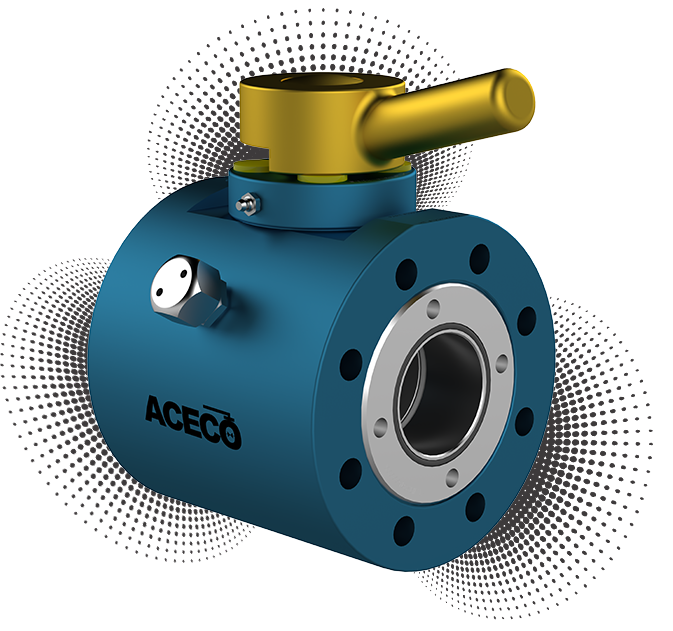

Trunnion Mounted Ball Valve

Double Ball Valve

Subsea Valve

Manifold System

Gas Measurement Flanges

Floating Ball Valve

Check Valve

Pigging Valve

Trunnion Mounted Ball Valve

Double Ball Valve

Subsea Valve

Manifold System

Gas Measurement Flanges

Floating Ball Valve

Check Valve

Pigging Valve

Trunnion Mounted Ball Valve

Double Ball Valve

Subsea Valve

Manifold System

Gas Measurement Flanges

Floating Ball Valve

Check Valve

Pigging Valve

Trunnion Mounted Ball Valve

Double Ball Valve

Subsea Valve

Manifold System

Gas Measurement Flanges

Floating Ball Valve

Check Valve

Pigging Valve

Trunnion Mounted Ball Valve

Double Ball Valve

Subsea Valve

Manifold System

Gas Measurement Flanges

Floating Ball Valve

Check Valve

Pigging Valve

Trunnion Mounted Ball Valve

Double Ball Valve

Subsea Valve

Manifold System

Gas Measurement Flanges

Floating Ball Valve

Check Valve

Pigging Valve

Trunnion Mounted Ball Valve

Double Ball Valve

Subsea Valve

Manifold System

Gas Measurement Flanges

Floating Ball Valve

Check Valve

Pigging Valve

Trunnion Mounted Ball Valve

Double Ball Valve

Subsea Valve

Manifold System

Gas Measurement Flanges

Floating Ball Valve

Check Valve

Pigging Valve

Trunnion Mounted Ball Valve

Values You Can Trust

Complementary services to help you achieve your project needs

About Us

Best In class

Having been in business for more than 30 years, and a collective 200 years of experience on the leadership team, you can trust Aceco Valve with your projects and needs. Whether you are looking for Ball, Check, Pigging, Throttle or Metal Seated Valves, you’ve come to the right place! Our expanded Manifold System and Component offerings allow for turn-key solutions! Need a customized solution? Let our engineers work out a solution for your specific needs!

Our Partners

FAQ

- Weight = up to 70% less

- Length = up to 40% less

- Height = up to 25% less (relative to bonnet)

- Torque = up to 70% reduction trunnion design (BV2)

- Fewer Seal Areas (leak paths)

- 5 Valve Manifolds

- 3 Valve Dehydrator Separators

- Blow Down Applications

- Choke and Kill Manifolds

- Connector Systems

- Drilling

- Drilling Diverter Valves

- Flow Back Manifolds

- Flow Lines

- Gooseneck Connectors

- High Pressure Gas Separators and Pump Manifolds

- Hot Oil Trucks

- Hot Stabs

- Injection Heads

- Managed Pressure Drilling (Mpd) (Systems Including Flow Spools, Bleed and Equalization Lines)

- Methanol Injection Service

- Mud Service

- Offshore Chemical Injection Packages

- Offshore Production and Test Manifolds

- Onshore Location Well Hookups

- Onshore Production and Separation Units

- Pig Launchers and Receivers (Plr)

- Pump Skids

- Sales Lines

- Separator Units

- Standpipe Manifold Service

- Trip Tank and Booster Line

- Water Flood and Co2 Injection

- Well Head Wing Valves

- Boarding Valves and ESDV’s*

- Cementing and Acidizing*

- FPSO Turret Manifolds*

- Frac Valves*

- Permanent Service

- Temporary Service

- Energized with wavo style Inconel X750 nickel alloy springs (red), to ensure low pressure and gas seal

- Nitride coated ball & seat

- Tungsten Carbide Coating for Severe service

- Tungsten Carbide coated ball and seat are Mate lapped for superior sealing (red)

- Recommended for critical High Pressure Applications

- Superior Chemical resistance

- Expands Temperature range compared to elastomers

- 1” – 4” for pressures ranging from 3,705 up to 15,000 PSI

- Designed to meet the demands of virtually all throttling applications

- Flow bore contour is engineered specifically for high pressure drop throttling service with precise linear control throughout the operating range

- Delivers higher flow rates than most positive chokes, when full open

- Flow indicator for precise flow control

- Ball design minimizes seat erosion

- Acetal and Peek Seat Materials

- Multiple elastomers available

- Exotic Materials available

- Metal Seated

- Throttling

- Lip Seal

- Locking Device

- Complete Automated Packages

- Internal/External Coatings

Manifold systems are used extensively throughout the oil and gas industry for the distribution of fluids and gases. They are

designed to converge multiple junctions into a single channel

or diverge a single channel into multiple junctions.

Connections are designed for easy valve removal without significant line spread.

Key Features

- Designed to accommodate High Pressure service up to 15,000 PSI,

available in nominal sizes from 1” to 12”. - Building block design allows for a wide variety of connection options

and design configurations. - Blocks, Tees, crosses, valves and end connections are designed to

minimize transition areas and erosion points. - Bolted connections and minimal line spread allow for ease of disassembly for maintenance and/or repair work.

System Components

- Ball Valves

- Check Valves

- Throttle Ball Valves

- Tube Connectors

- 3-Way Blocks

- 4-Way Blocks

- 5-Way Blocks